Press Release

For highly active, sustainable catalysts, just add phosphorus

ASSOCIATE PROFESSOR. Takato Mitsudome

Catalysts are crucial to making industrial processes viable. However, many of the non-precious metal catalysts used for synthesis have low activity, are difficult to handle, and/or require harsh reaction conditions. Osaka University researchers have developed a single-crystal cobalt phosphide nanorod catalyst that overcomes several of the limitations of conventional cobalt catalysts. Their findings were published in JACS Au.

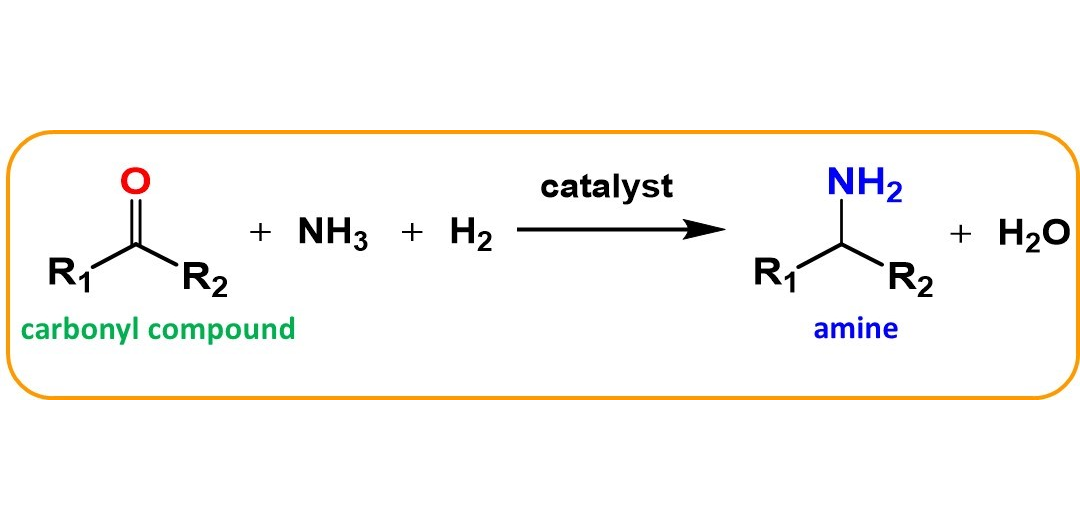

Reductive amination is an important chemical reaction that is used to convert carbonyl compounds into amines. It is a key step in the production of many materials such as polymers, dyes, and pharmaceuticals, and is attractive because the reagents are cost effective and widely available, and the main byproduct is water.

The catalysts currently used for reductive amination are generally non-precious metal catalysts such as cobalt and nickel sponges. However, they are highly sensitive to air, and this makes them difficult to handle without deactivation. They also require harsh reactions conditions, such as high H2 pressures, which increases energy and infrastructure costs. Therefore, the development of a new air-stable and highly active catalyst is highly desired.

The researchers prepared a single-crystal cobalt phosphide nanorod catalyst for the reductive amination of carbonyl compounds. The introduction of phosphorus into the cobalt—a method called “phosphorus-alloying”— makes the cobalt active and stable in air. It also creates well-defined active sites in the crystal structure, which lead to more selective reactions compared with those on conventional catalysts.

“Our nanorod is the first metal-phosphide catalyst that has been used for reductive amination, as well as being the first cobalt catalyst that is effective at atmospheric pressure,” study first author Min Sheng explains. “Furthermore, our catalyst showed the highest turnover number of all homogeneous and heterogenous non-precious metal catalysts tested for the same reaction.”

The nanorod catalyst retains the high activity after 4 uses, which demonstrates that it is a viable alternative for use in processes requiring high throughput.

“We expect our nanorod catalyst to make a significant contribution to the cost and energy efficient production of amines,” says study corresponding author Takato Mitsudome. “But beyond this, we believe phosphorus-alloying has the potential to enhance the catalysis for many other organic reactions, leading to greener and more sustainable processes that improve productivity, conserve energy resources, and avoid the reliance on hazardous compounds while protecting our environment.”

Fig. 1. Reductive amination of carbonyl compounds

As delay time needs to be taken into account to consider external radiation, U and A are affected by the charge density q and current density j, which have some delay times that depend on space. Thus, to precisely consider the delay, it is necessary to perform a complex spatial integration calculation with a time shift.

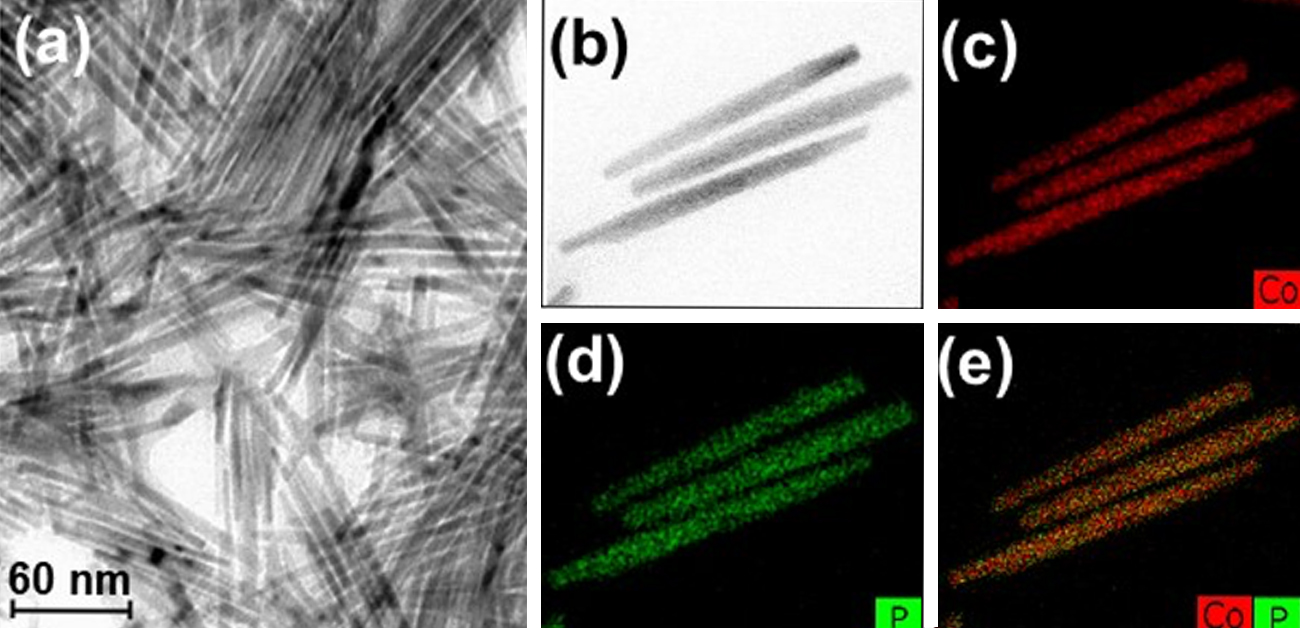

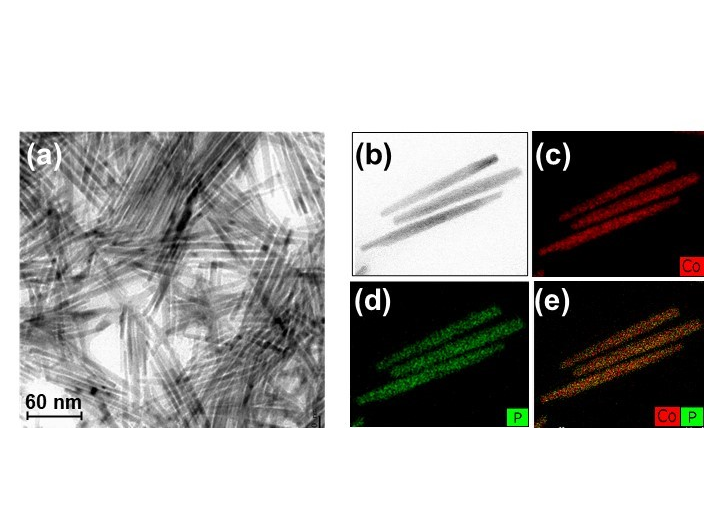

Fig. 2. Cobalt phosphate nanorods: (a) microscope image and (b-e) element mapping image

The article, “Single-crystal cobalt phosphide nanorods as a high-performance catalyst for reductive amination of carbonyl compounds,” was published in JACS Au at DOI: https://pubs.acs.org/doi/abs/10.1021/jacsau.1c00125.

Please see ResOU for the detail.